Table of Contents

The tech world was taken by storm when news broke about a potential partnership between Tim Cook’s leadership and the Trump administration regarding domestic iPhone production. This groundbreaking initiative represents more than just a business deal—it’s a strategic shift that could reshape the entire landscape of American manufacturing and technology production.

The Genesis of the $600B Deal: How It All Started

The foundation of this unprecedented agreement can be traced back to strategic conversations between Tim Cook’s Trump discussions that began taking shape during policy meetings focused on bringing technology manufacturing back to American soil. The Apple CEO has long been interested in exploring opportunities for US manufacturing, and recent political climate changes have created the perfect storm for such ambitious undertakings.

This massive investment commitment showcases how major technology companies are reconsidering their global supply chain strategies. The deal represents a significant shift from traditional overseas production models, with Tim Cook’s positioning itself as a pioneer in domestic technology manufacturing. The Apple company has historically relied on international production facilities, making this domestic pivot particularly noteworthy.

What makes this partnership especially compelling is the scale of investment involved. The $600 billion commitment isn’t just about manufacturing—it’s about creating an entire ecosystem of American-based technology production that could serve as a model for other companies in the sector.

The Economic Impact: What a U.S. Made iPhone Means for the American Economy

The economic implications of this deal extend far beyond the immediate manufacturing scope. Industry analysts predict that domestic iPhone production could create hundreds of thousands of jobs across various sectors, from direct manufacturing positions to supporting roles in logistics, quality control, and supply chain management.

This initiative could spark a renaissance in American manufacturing, particularly in the technology sector. When major companies like Apple commit to domestic production, it often creates ripple effects that encourage suppliers and partners to establish local operations as well. The multiplier effect of such investments typically generates economic activity that extends well beyond the initial commitment.

Local communities in designated manufacturing areas are expected to experience significant economic growth. From construction jobs during facility development to long-term manufacturing positions, the employment opportunities created by this deal could revitalize entire regions. The focus on creating high-quality, well-paying jobs aligns with broader economic development goals.

Media reporting on the significant announcement

AP: Trump Says Apple to Invest Additional $100 Billion in US Manufacturing

Bloomberg: Trump, Apple Bear $100 Billion US Investment Together On

Breitbart: Trump and Apple’s Tim Cook’s Together $600 Billion Investment In America

CBS News: Trump and Apple are Together Commencing Investment of Additional $100 Billion US Manufacturing

CNN: Apple pledges $100 billion for US iPhone parts manufacturing as Trump threatens hefty chip tariffs

The Daily Caller: Trump Says Apple’s New Investment In America

The Daily Wire: Trump Previously Wrote Off Claim Apple Would Invest $100 Billion In The US Economy

Fox News: Apple Set To Make $100B US Investment Announcement Roughly Manufacturing

Los Angeles Times: Apple Set To Make Additional $100 Billion Investment In Manufacturing Us while The White House Expects

NBC News: Announcement Apple Investment Trump To Host

NewsNation: Apple further invests $100 billion in US

New York Post: Trump tariffs force India, Apple pledged $100 billion for US manufacturing

The New York Times: Trump Discloses $100 Billion Additional Investment Apple Will Make In Us

Reuters: A White House said that Apple will pledge $100 billion for US manufacturing.

The Hill: Trump Apple Announces $600B US Manufacturing Investment

TIME: Apple to Pledge $100BN Investment in US manufacturing During Trump Meeting

USAToday: Trump And Apple to Give $100BN Investment During US Tariff Frenzy

The Wall Street Journal: Apple Commits Additional $100B in US Manufacturing Investment

Challenges and Opportunities: Navigating the Complexities of Domestic Manufacturing

Transitioning from international to domestic production presents numerous challenges that Tim Cook’s must carefully navigate. Manufacturing costs in the United States are typically higher than in traditional production locations, which means the company needs to find innovative ways to maintain competitive pricing while ensuring profitability.

Supply chain logistics represent another significant hurdle. Creating a domestic supply chain requires establishing relationships with local suppliers, ensuring quality standards, and maintaining the reliability that consumers expect from Apple products. This transition period will likely require substantial investment in infrastructure and training.

However, these challenges also present unique opportunities. Domestic production offers greater control over quality standards, faster response times to market demands, and reduced vulnerability to international trade disruptions. The company can also leverage advanced manufacturing technologies and automation to offset higher labor costs.

Global Perspectives: How Does This Deal Affect International Relations?

This domestic manufacturing initiative has significant implications for global trade relationships. The shift toward American production could influence international trade patterns and potentially impact relationships with current manufacturing partners in other countries.

The move also signals a broader trend toward supply chain localization, which has gained momentum following recent global disruptions. Other multinational corporations are closely watching how this initiative unfolds, as it could serve as a blueprint for similar domestic manufacturing strategies.

From a diplomatic perspective, this deal demonstrates how business partnerships can align with national economic policies. The collaboration between private enterprise and government initiatives showcases a model for public-private partnerships in manufacturing development.

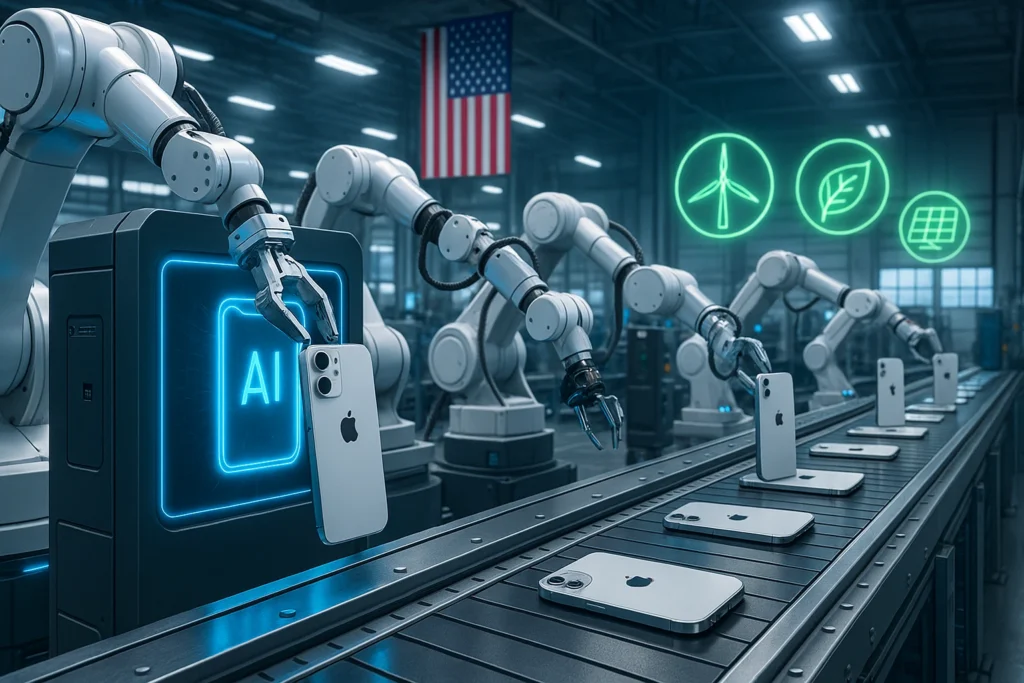

The Role of Innovation in Making U.S. Based Production a Reality

Tim Cook’s success in domestic manufacturing will largely depend on its ability to innovate in production processes. The company has always been at the forefront of technological advancement, and this initiative provides an opportunity to revolutionize manufacturing approaches.

Advanced automation, artificial intelligence in quality control, and sustainable production practices are all expected to play crucial roles in making domestic production economically viable. These innovations could set new standards for manufacturing efficiency and environmental responsibility.

The integration of cutting-edge technology in manufacturing processes could also create new intellectual property opportunities and establish Tim Cook’s Apple as a leader in advanced manufacturing techniques.

User Perception and Market Response to U.S. Made iPhones

Consumer reaction to domestically manufactured iPhones has been largely positive, with many expressing enthusiasm for supporting American-made products. Market research indicates that a significant portion of consumers are willing to pay premium prices for products manufactured domestically, especially when quality standards remain high.

The “Made in Apple USA” branding could become a powerful marketing advantage, appealing to consumers who prioritize supporting local manufacturing. This positioning could differentiate Tim Cook’s Apple products in an increasingly competitive marketplace.

Brand loyalty impacts are expected to be positive, particularly among consumers who value corporate responsibility and domestic economic support. The initiative aligns with broader consumer trends toward supporting companies that demonstrate commitment to local communities.

Conclusion: Why Tim Cook’s Strategic Move Could Change the Future of Tech Manufacturing Forever

The partnership between Tim Cook‘s and the Trump administration represents more than just a business deal—it’s a potential catalyst for transforming American manufacturing. This initiative could establish new precedents for how technology companies approach production strategies and supply chain management.

The success of Tim Cook’s $600B investment could encourage other major technology companies to explore similar domestic manufacturing opportunities. If Apple can demonstrate that high-quality, cost-effective production is possible in the United States, it could spark a broader renaissance in American manufacturing.

Looking toward Apple 2025 and beyond, this initiative positions the company as a pioneer in domestic technology production. The lessons learned and innovations developed through this process could influence manufacturing strategies across the entire technology sector.

The vision of American-made iPhones represents more than just a change in production location—it symbolizes a commitment to domestic economic development and technological innovation that could reshape the future of American manufacturing.

FAQ

Q: When will U.S. made iPhones be available to consumers?

A: While specific timelines haven’t been officially announced, industry experts expect the transition to domestic production to be gradual, with initial products potentially available within the next few years.

Q: Will domestically manufactured iPhones cost more than current models?

A: Apple has indicated its commitment to maintaining competitive pricing, though some premium may be expected initially as domestic production scales up.

Q: How many jobs will this initiative create?

A: Estimates suggest hundreds of thousands of jobs could be created directly and indirectly through this manufacturing initiative.

Q: What impact will this have on Apple’s international operations?

A: The company plans to maintain global operations while expanding domestic capabilities, creating a more diversified manufacturing approach.

Q: Will the quality of U.S. made iPhones match current standards?

A: Apple has committed to maintaining its high quality standards regardless of production location, with advanced quality control measures planned for domestic facilities.